Flowline Installation and Hook-up at WP2 & WP4

This scope involves the installation and hook-up of flowlines on Well Platform 2 (WP2) and Well Platform 4 (WP4) to support production from existing and new wells. At WP2, new flowlines are installed to connect the X-mas tree Yad-2M to the existing flowline Yad-2I.

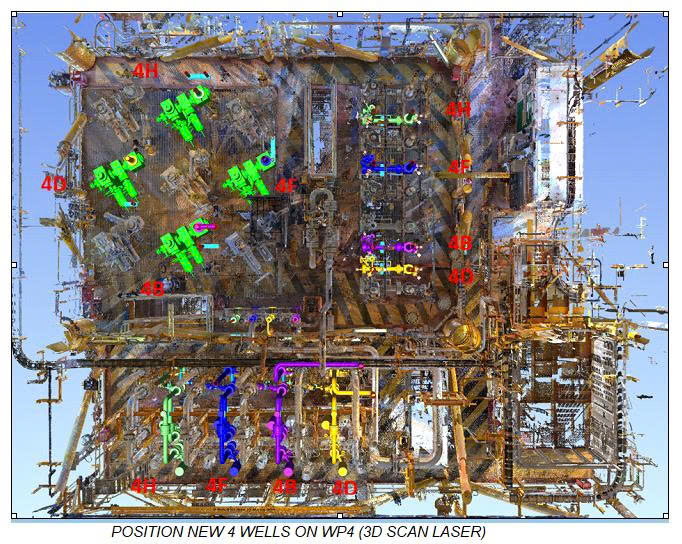

At WP4, four new 6-inch flowlines connect new X-mas trees to both production and test manifolds. WP4 features nine well slots, with five currently in production.

Piping & Structural Works

- Conduct site surveys, including 3D laser scanning, to determine optimal routing for flowlines.

- Demolish existing piping, install blind flanges, and perform detailed engineering and stress analysis.

- Perform Non-Destructive Testing (NDT) including X-ray and Phased Array Ultrasonic Testing (PAUT) for all field welds.

- Conduct hydrostatic testing on all fabricated piping spools.

- Perform low-pressure leak testing on tie-in valves and nitrogen leak testing on the complete system.

- install access platforms, including required modifications to existing structures.

- (Scope covers both onshore fabrication and offshore installation.)

Electrical & Instrumentation (E&I) Works

- Execute all E&I works, including tubing installation between X-mas trees, Wellhead Control System (WHSC), and override stations. Perform hydraulic flushing and functional testing of instrumentation flowlines on both WP2 & WP4.

- Install various instrumentation, including gauges, transmitters, flow meters, cable trays, supports, instrument tubing, and hydraulic tubing for chokes, actuated valves, and X-mas trees.

Pre-Commissioning & Commissioning

- Develop and execute pre-commissioning and commissioning procedures, including check sheets and test plans, upon completion of drilling and hook-up works.

- Conduct function testing for all subsystems and equipment related to the new flowlines on WP2 and WP4.

- Perform troubleshooting, record all malfunctions, and complete hydraulic flushing of tubing.

- Operate and verify proper function of actuated valves, choke valves, and X-mas tree valves.

- Execute loop checks, calibration, and functional testing of all transmitters (pressure, temperature, flow, level), control valves, and chokes.

- Perform configuration and testing for flow transmitters.

- Develop and perform Operational Test Procedures (OTP) before and after gas-in.